Equipment functions

1. Customized suction cups are equipped with independent and generator functions, with automatic suction cup adjustment to reduce the time required for changing boards and adjusting suction cups.

2. The motion mechanism is a single 6-axis robotic arm for collecting and placing boards, with a long service life and high stability.

3. The dual station robotic arm folding and releasing machine has two stations, and after the single station is fully loaded, it automatically switches to uninterrupted production.

4. There are 4 shaking cylinders on the plate suction mechanism of the loading machine, which shake during plate suction to prevent multiple plates from being sucked at once.

5. The receiving machine has an NG station, and if there are NG boards, they can be automatically placed in the NG station.

6. The clapping board has a top center clapping board to ensure that the boards are placed and collected neatly without scratching the board surface.

7. The discharge port of the loading machine has a dual piece detection function to prevent multiple boards from flowing out.

8. The equipment is reserved with connected IO signals and a network port for communication with the MES system.

9. Compatible with fixed trolley and AGV trolley upper and lower plates.

10. The conveying part can be equipped with magnetic transmission, which is non-contact and does not pose a risk of wear and debris.

11. The welding structure of the rack is sturdy and not easily deformed, and A3 steel frame baked orange pattern paint or 304 stainless steel can be selected according to the needs.

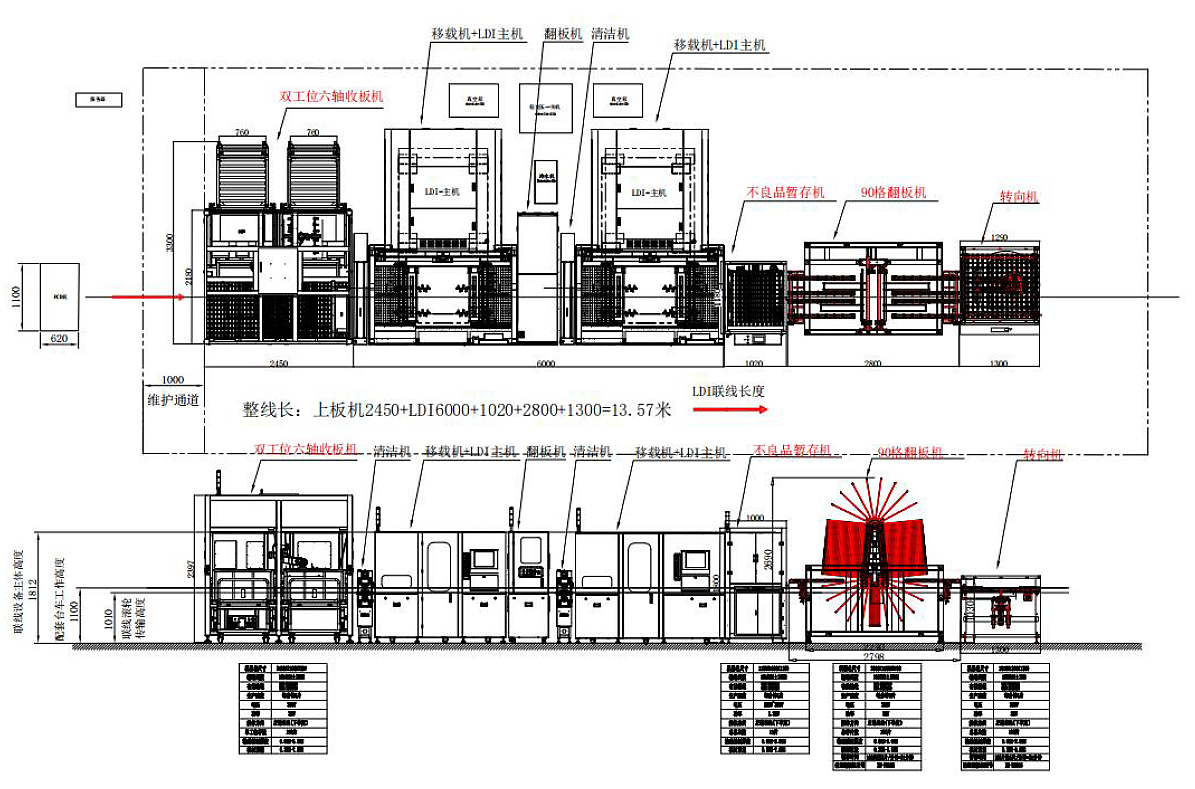

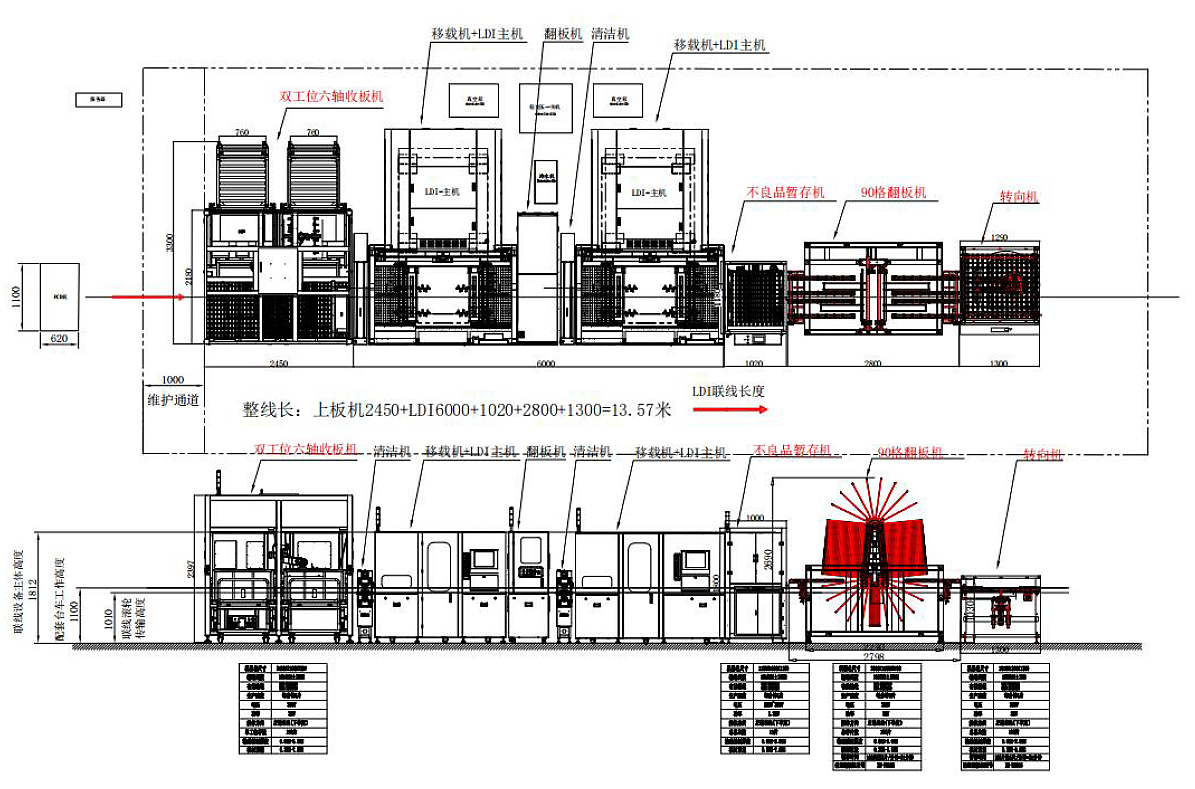

Equipment parameters:

Equipment dimensions (mm): length * width * height 1850X2100X2450

Homework height (mm): 1000/-50

Homework width (mm): 900

Transmission speed (M/ir): 1-8M/Min, adjustable speed

Power consumption (KW): single-phase C220V2.5XW

Working pressure (MPa): 0.6MPa

Maximum board size (mm): 735 * 635

Minimum board size (mm): 300 * 300

Applicable thickness (mm): 0.05-4.0

Load capacity (mm): 220

Standard production speed (Pcs/Min): 8Pcs/Min

Equipment weight (KG): 1000KG

Phone: 0755-27387080

Phone: 0755-27387080 Mobile: 13609613568

Mobile: 13609613568 Contact: Mr. Su

Contact: Mr. Su Email: sysu@sanyingtech.com

Email: sysu@sanyingtech.com Website: m.fairfoxeon-org.com

Website: m.fairfoxeon-org.com Address: Dahong Technology Innovation Park, No. 48 Xinyu Road, Xinqiao Street, Bao'an District, Shenzhen

Address: Dahong Technology Innovation Park, No. 48 Xinyu Road, Xinqiao Street, Bao'an District, Shenzhen